When it comes to the application of industrial fluoropolymer coating, there are several options available to you. These are likely companies that would apply high quality sealants and follow certain industry guidelines to ensure that you get a good product in the end. The final choice in what coating company you choose however rests in the culmination of several deciding factors.

When it comes to the application of industrial fluoropolymer coating, there are several options available to you. These are likely companies that would apply high quality sealants and follow certain industry guidelines to ensure that you get a good product in the end. The final choice in what coating company you choose however rests in the culmination of several deciding factors.

It is no secret that post-pandemic, industrial plants

Coating Solutions specializes in applying a wide variety of Chemours®® Teflon™ coating parts and equipment used in all types of industries. Our coating specialists work with many different companies in the food processing industry all over the country. Teflon coating can be used on equipment such as waffle irons, bread pans, mixers, beaters, hoppers, and dough rollers to keep sticky and wet substances like flour and sugar from sticking, making it very difficult to clean. Teflon™ coating also extends the life of these items, allowing them to stay in production for longer, saving your company money.

Coating Solutions specializes in applying a wide variety of Chemours®® Teflon™ coating parts and equipment used in all types of industries. Our coating specialists work with many different companies in the food processing industry all over the country. Teflon coating can be used on equipment such as waffle irons, bread pans, mixers, beaters, hoppers, and dough rollers to keep sticky and wet substances like flour and sugar from sticking, making it very difficult to clean. Teflon™ coating also extends the life of these items, allowing them to stay in production for longer, saving your company money. Fluorinated ethylene propylene (FEP) is an ISO 9001-certified coating that offers several distinct advantages as a coating material. Chemours®’s FEP coatings are a great option to use for non-stick, corrosion- and chemical-resistant applications. This coating is an excellent option for applications that require some of the advantages of PTFE coatings

Fluorinated ethylene propylene (FEP) is an ISO 9001-certified coating that offers several distinct advantages as a coating material. Chemours®’s FEP coatings are a great option to use for non-stick, corrosion- and chemical-resistant applications. This coating is an excellent option for applications that require some of the advantages of PTFE coatings The 3-coat reinforced system is the premium Teflon® industrial coating line for end uses that require nonstick, abrasion or scratch resistance, thermal stability to 500° F, and durability in a thin film fluoropolymer coating. This water-based, multi-coat system is a unique blend of PTFE, PFA, and FEP combined with ceramic fillers. For additional durability, ceramic fillers have been added to the primer and mid-coat layers. The primer utilizes On-Smooth technology. Decades of innovation and technology

The 3-coat reinforced system is the premium Teflon® industrial coating line for end uses that require nonstick, abrasion or scratch resistance, thermal stability to 500° F, and durability in a thin film fluoropolymer coating. This water-based, multi-coat system is a unique blend of PTFE, PFA, and FEP combined with ceramic fillers. For additional durability, ceramic fillers have been added to the primer and mid-coat layers. The primer utilizes On-Smooth technology. Decades of innovation and technology Teflon is the brand name that commercializes this product, but the coating itself is called Polytetrafluoroethylene or PTFE. There are mainly two types of PTFE coatings such as one-coat PTFE and two-coat PTFE that consists of a primer and a topcoat. At Coating Solutions, they are used in various applications because of their impressive list of advantages.

Teflon is the brand name that commercializes this product, but the coating itself is called Polytetrafluoroethylene or PTFE. There are mainly two types of PTFE coatings such as one-coat PTFE and two-coat PTFE that consists of a primer and a topcoat. At Coating Solutions, they are used in various applications because of their impressive list of advantages. It’s 100% true that every industry, every company, and every person has a decision to choose where they do business and who they do business with. It’s no secret that the coating industry is predominantly male. So, when our company, Coating Solutions, began in 1995, company owners, Dawn and Kim, knew they would have to give it their all. Started by these two sisters, Coating Solutions has grown to be

It’s 100% true that every industry, every company, and every person has a decision to choose where they do business and who they do business with. It’s no secret that the coating industry is predominantly male. So, when our company, Coating Solutions, began in 1995, company owners, Dawn and Kim, knew they would have to give it their all. Started by these two sisters, Coating Solutions has grown to be When it comes to choosing the ideal coating for your product, you can’t go wrong with Chemours® Teflon® coating. Finding the right company to handle your Chemours® Teflon® coating needs in a timely manner is not as easy as it may sound. Once you work with our Chemours® Teflon® coating experts at Coating Solutions, we’re confident that you’ll come back to us every time.

When it comes to choosing the ideal coating for your product, you can’t go wrong with Chemours® Teflon® coating. Finding the right company to handle your Chemours® Teflon® coating needs in a timely manner is not as easy as it may sound. Once you work with our Chemours® Teflon® coating experts at Coating Solutions, we’re confident that you’ll come back to us every time. In almost every single industry, Chemours® Teflon® and fluoropolymer coatings have been an extremely useful tool in helping companies do their job more smoothly and efficiently. Industrial coatings offer many advantages to products and machinery. It allows for abrasion resistance, temperature stability, chemical resistance, nonstick properties as well as a dry lubricant feel. It’s no secret that Chemours® Teflon® and fluoropolymer are helpful tools that allow many different industries to run more efficiently. However, industrial coating applications will only take you so far. Chemours® Teflon® and fluoropolymer only does its job well when it is applied well. At Coating Solutions, we provide Chemours® Teflon® and fluoropolymer coating results that are impeccable every application.

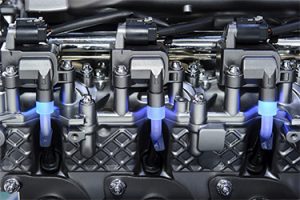

In almost every single industry, Chemours® Teflon® and fluoropolymer coatings have been an extremely useful tool in helping companies do their job more smoothly and efficiently. Industrial coatings offer many advantages to products and machinery. It allows for abrasion resistance, temperature stability, chemical resistance, nonstick properties as well as a dry lubricant feel. It’s no secret that Chemours® Teflon® and fluoropolymer are helpful tools that allow many different industries to run more efficiently. However, industrial coating applications will only take you so far. Chemours® Teflon® and fluoropolymer only does its job well when it is applied well. At Coating Solutions, we provide Chemours® Teflon® and fluoropolymer coating results that are impeccable every application. The number one cause of mechanical failure in most any piece of production equipment is failed bearings within the machine. An increase in vibration and excessive heating are often the culprit behind a failed bearing. A Teflon coating, however, increases mechanical properties and provides greater temperature resistance. After getting its start from being used to coat valves and prevent leak points in the nuclear bomb constructed during The Manhattan Project, the Polytetrafluoro Ethelyne product known as Teflon has soared in popularity and is now found in countless applications across many industries.

The number one cause of mechanical failure in most any piece of production equipment is failed bearings within the machine. An increase in vibration and excessive heating are often the culprit behind a failed bearing. A Teflon coating, however, increases mechanical properties and provides greater temperature resistance. After getting its start from being used to coat valves and prevent leak points in the nuclear bomb constructed during The Manhattan Project, the Polytetrafluoro Ethelyne product known as Teflon has soared in popularity and is now found in countless applications across many industries. You may be very familiar with the many benefits of Teflon® and fluoropolymer coating for your parts and equipment. What you may not be as familiar with are the specifics of the coating application process. Coating Solutions has been

You may be very familiar with the many benefits of Teflon® and fluoropolymer coating for your parts and equipment. What you may not be as familiar with are the specifics of the coating application process. Coating Solutions has been