In today’s fast-paced world, where innovation and protection go hand in hand, the significance of coating solutions cannot be overstated. From industrial applications to residential needs, coatings play a pivotal role in enhancing

In today’s fast-paced world, where innovation and protection go hand in hand, the significance of coating solutions cannot be overstated. From industrial applications to residential needs, coatings play a pivotal role in enhancing

Coating Solutions Blog

Unleashing The Potential Of Your Surfaces With PFE Coating

In today’s fast-paced world, businesses and industries are constantly seeking innovative solutions to enhance the durability, performance, and longevity of their products. When it comes to surface protection, PFE (Polytetrafluoroethylene) coating applications have emerged as a game-changer. PFE coating offers a wide range of benefits that can revolutionize your products and take

In today’s fast-paced world, businesses and industries are constantly seeking innovative solutions to enhance the durability, performance, and longevity of their products. When it comes to surface protection, PFE (Polytetrafluoroethylene) coating applications have emerged as a game-changer. PFE coating offers a wide range of benefits that can revolutionize your products and take

Scheduling Fluoropolymer Industrial Coating Application

When is your business’ busy time of year? For some businesses, the busiest time of year are the holidays in December and January, from other businesses, it is the summer months. It is important to make sure that your equipment is efficient and working correctly especially during those busy times. Adding Chemours® Teflon® and fluoropolymer industrial coatings to your parts and equipment to help with cleaning

When is your business’ busy time of year? For some businesses, the busiest time of year are the holidays in December and January, from other businesses, it is the summer months. It is important to make sure that your equipment is efficient and working correctly especially during those busy times. Adding Chemours® Teflon® and fluoropolymer industrial coatings to your parts and equipment to help with cleaning

Kynar Coating Offers Versatility In Many Applications

Kynar coating applications have long been seen as a solution for protecting and prolonging the longevity of various surfaces, thanks to their outstanding durability, chemical resistance, and versatility. Coating Solutions in Hugo, MN applies it regularly. In this blog post, we will explore its many uses and benefits and demonstrate why Kynar is often chosen over other materials for various applications.

Kynar coating applications have long been seen as a solution for protecting and prolonging the longevity of various surfaces, thanks to their outstanding durability, chemical resistance, and versatility. Coating Solutions in Hugo, MN applies it regularly. In this blog post, we will explore its many uses and benefits and demonstrate why Kynar is often chosen over other materials for various applications.

Professional Coating Application For Your Business

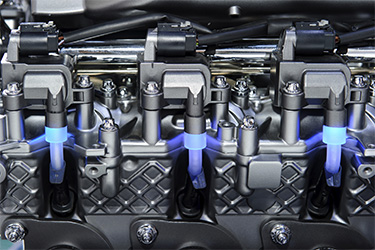

When it comes to running a business, you have a lot on your plate. Marketing, payroll, production just to name a few. One thing that most business owners agree on is the need for efficiency in all aspects of business. Keeping your parts and equipment working efficiently is critical to being able to produce your product quickly. One thing that can be extremely helpful with this process is adding a professional DuPont Teflon® and fluoropolymer industrial coating. Coating Solutions specializes in DuPont Teflon® and fluoropolymer industrial coating application and our focus is on making the coating application process easy and efficient for you and your business.

When it comes to running a business, you have a lot on your plate. Marketing, payroll, production just to name a few. One thing that most business owners agree on is the need for efficiency in all aspects of business. Keeping your parts and equipment working efficiently is critical to being able to produce your product quickly. One thing that can be extremely helpful with this process is adding a professional DuPont Teflon® and fluoropolymer industrial coating. Coating Solutions specializes in DuPont Teflon® and fluoropolymer industrial coating application and our focus is on making the coating application process easy and efficient for you and your business.

Fluoropolymer Coating Application Specialists In Minnesota

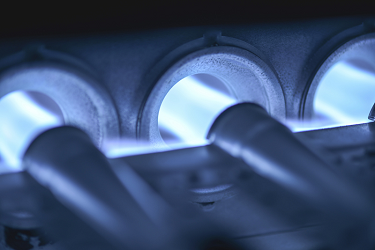

The durability and versatility of Fluoropolymers has led to its being called a “super-paint”. Fluoropolymers have many advantages for industrial applications. Coating Solutions, located in Hugo Minnesota, offers several types of fluoropolymers to reduce wear on industrial parts and extend their life.

The durability and versatility of Fluoropolymers has led to its being called a “super-paint”. Fluoropolymers have many advantages for industrial applications. Coating Solutions, located in Hugo Minnesota, offers several types of fluoropolymers to reduce wear on industrial parts and extend their life.

Selecting The Right Fluoropolymer For Your Application

There are dozens of different fluoropolymer options available on the market. Each one has its own performance, thickness, and application properties. Coating Solutions’ fluoropolymer coating experts have years of experience that allows them to know intuitively what to do. Fluoropolymer selection can be a “process of elimination” that is often necessary.

There are dozens of different fluoropolymer options available on the market. Each one has its own performance, thickness, and application properties. Coating Solutions’ fluoropolymer coating experts have years of experience that allows them to know intuitively what to do. Fluoropolymer selection can be a “process of elimination” that is often necessary.

What is the function you would like it to perform? Most of the time, a customer will ask a fluoropolymer to perform a single primary function.

Benefits Of PFA Coatings

Teflon™ perfluoroalkoxy (PFA) industrial coatings melt and flow during baking to form nonporous films, offering superior nonstick properties suitable for industrial bakeware applications. With higher continuous use temperatures (500degF), superior dielectric strength, and chemical resistance properties, Teflon™ PFA industrial coatings are more

Teflon™ perfluoroalkoxy (PFA) industrial coatings melt and flow during baking to form nonporous films, offering superior nonstick properties suitable for industrial bakeware applications. With higher continuous use temperatures (500degF), superior dielectric strength, and chemical resistance properties, Teflon™ PFA industrial coatings are more

Benefits Of Coating Applications With PTFE

Teflon™ is a PTFE coating that has excellent non-stick/release characteristics. This means commercial bakeware can be easily cleaned and have excellent nonstick/release properties. We have designed a variety of PTFE systems that are suitable for most applications. The coating’s function and operating conditions will determine the best coating.

Teflon™ is a PTFE coating that has excellent non-stick/release characteristics. This means commercial bakeware can be easily cleaned and have excellent nonstick/release properties. We have designed a variety of PTFE systems that are suitable for most applications. The coating’s function and operating conditions will determine the best coating.

Nonstick and Release: The PTFE coating will provide excellent non-stick/release characteristics and is easy to clean. This coating also prevents both hot and cool products

Teflon™ Applications In Cabling And Communications

Infrastructures need reliable communications systems to transmit data and information and stay connected. Data transmission efficiency is determined by the quality of cable and wire insulation. Fluoropolymers of high quality allow for thinner and lighter wire and cable insulation walls.

Infrastructures need reliable communications systems to transmit data and information and stay connected. Data transmission efficiency is determined by the quality of cable and wire insulation. Fluoropolymers of high quality allow for thinner and lighter wire and cable insulation walls.

13525 Fenway Blvd N

Hugo, MN 55038

Phone: (651) 762-5700

Hours: M - F 7:00 - 3:30

Request A Quote

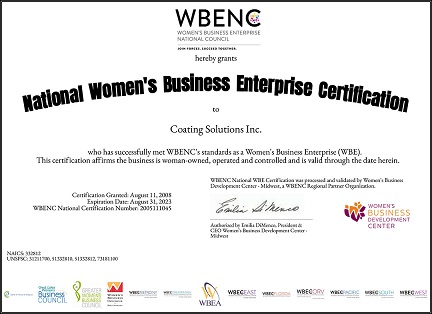

Woman Owned Business

Our Customers

|

|

|

|