Diverse Applications of Teflon Coatings

The number one cause of mechanical failure in most any piece of production equipment is failed bearings within the machine. An increase in vibration and excessive heating are often the culprit behind a failed bearing. A Teflon coating, however, increases mechanical properties and provides greater temperature resistance. After getting its start from being used to coat valves and prevent leak points in the nuclear bomb constructed during The Manhattan Project, the Polytetrafluoro Ethelyne product known as Teflon has soared in popularity and is now found in countless applications across many industries.

The number one cause of mechanical failure in most any piece of production equipment is failed bearings within the machine. An increase in vibration and excessive heating are often the culprit behind a failed bearing. A Teflon coating, however, increases mechanical properties and provides greater temperature resistance. After getting its start from being used to coat valves and prevent leak points in the nuclear bomb constructed during The Manhattan Project, the Polytetrafluoro Ethelyne product known as Teflon has soared in popularity and is now found in countless applications across many industries.

Teflon Makes A Product’s Effective Lifespan Increase

Teflon’s ability to reduce friction not only keeps industrial equipment cooler and running longer without fail, but you may be surprised to learn that the same properties also keep skiers safe by allowing bindings to separate from their skis during a fall.

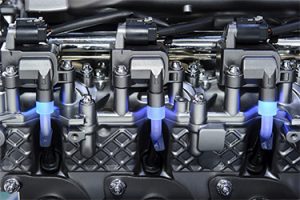

The automotive industry is another area where Teflon is used with more and more regularity. The coating’s nonstick factors may be best known for letting bacon slide off the pan, but there are plenty of car parts that manufactures need to keep from sticking to other parts over the life of the vehicle.

You might expect the axles and ball bearings to contain Teflon, but did you know that the miracle coating is often found on windshield wipers and seatbelt clips as well? After all, owners need their wipers to avoid sticking to the windshield and the Teflon coating makes it possible even in extreme heat.

If fasteners and other parts exposed to the elements are coated with Teflon, there is a much lower chance of mold or mildew growing on the equipment. Using a Fluoropolymer coating prevents corrosion and protects parts from degradation for years.

Teflon Coating Solutions For A Bright Future

Teflon has been keeping valves and other pieces of equipment leak proof since its creation prior to World War II. Because it is a resin discovered in a laboratory, scientists are able to continue to improve on its attributes. Over the decades, Teflon has been made safer and more effective for its many uses across numerous industries.

From ski bindings to windshield wipers to whatever equipment you have that needs to experience lower temperatures and less friction, Coating Solutions knows how to make it happen. Coating Solutions uses a specific six step process, perfected over the past 25 years of coating parts with Teflon and other fluoropolymer coatings, to guarantee every customer’s satisfaction.

Call Coating Solutions at 651-762-5700 or use our online contact form to request more information on how Teflon can be used to improve your equipment.