Teflon Coating for Food Processing Rochester

Sticky sugars and moist flours can easily gunk up machines quickly. This can make it extremely difficult to keep production moving forward when these are the products you work with every day. Liquid lubricants are generally not an option when operating in the food processing industry as liquid can alter the consistency and flavor of food. And let’s be honest, wet bread is about as desirable as a rainy, forty degree June day. Chemours® Teflon® coatings and Whitford coatings are excellent choices for covering parts that are used in the commercial processing of food. Coating Solutions will coat any part that is required for food processing machinery in Rochester – that is, any part that can stand up to high cure temperatures.

Sticky sugars and moist flours can easily gunk up machines quickly. This can make it extremely difficult to keep production moving forward when these are the products you work with every day. Liquid lubricants are generally not an option when operating in the food processing industry as liquid can alter the consistency and flavor of food. And let’s be honest, wet bread is about as desirable as a rainy, forty degree June day. Chemours® Teflon® coatings and Whitford coatings are excellent choices for covering parts that are used in the commercial processing of food. Coating Solutions will coat any part that is required for food processing machinery in Rochester – that is, any part that can stand up to high cure temperatures.

Items We Typically Coat:

- Waffle Irons

- Bread Pans

- Mixers and Beaters

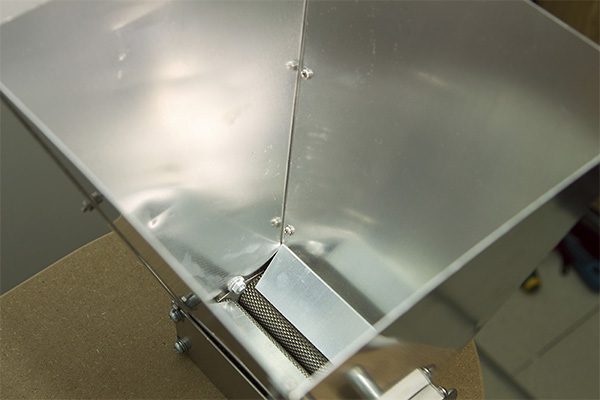

- Hoppers

- Bread Pans

- Dough Rollers

- Blades

Nonstick Coatings for Food Production Rochester

Fluoropolymer finishings are regularly selected as the ideal option for coating parts that are used in food processing machinery. Food has much less chance of clinging to fluoropolymers as opposed to other materials that are sometimes used in food processing these days. But it has many more uses than just ensuring that pork cutlets don’t stick and burn. The high release of fluoropolymers produces a much more uniformed result when products come out of molds. Flour doesn’t stick to large hoppers, and dough rollers can function nonstop. And they are FDA approved coatings, so you know that they are all right for contact with food. For the food processing industry, it’s a wise choice to have all parts that will be in contact with food coated with Teflon® or another fluoropolymer coating.

Financial Benefits of Teflon® and Fluoropolymers

The nonstick advantages of fluoropolymers means a higher output of product as machines are not turned off as regularly in order to remove buildup and scrape and clean. And when cleaning does need to occur, nonstick means that parts coated with fluoropolymers are a piece of cake to clean and are unaffected by strong cleaning chemicals. Less cleaning saves many businesses in Rochester additional cleaning agent usage and labor costs. And even more money can be saved because of the fact that equipment coated with fluoropolymers is generally less expensive than exotic and/or highly polished metals. Teflon® coated equipment also has a much longer lifespan than products fabricated with other material and, therefore, comes with lower maintenance expenses. This is all why covering parts with Teflon® and fluoropolymer coatings is the financially wise choice for many businesses in Rochester, MN.

Heat Resistance of Teflon® Coatings

Teflon® and fluoropolymer coatings are extremely resistant to heat, which makes them ideal for equipment used with food processing. These coatings can function excellently at continuous temperatures of up to 500°F (260°C), or 600°F at interrupted intervals. And, obviously, they can stand up to steam cleaning. Everything that is exposed to high heat during food processing, including pipes, valves, gaskets, and pumps can be coated with Teflon® and fluoropolymer coatings so that they can operate properly for a longer time periods. The cost-effectiveness of these coatings make them the best choice for companies working with food processing equipment.

Guaranteed Results for Food Processing Equipment

Coating Solutions sticks to an exceptionally high standard of quality. Offering fast turn around and the lowest minimum lot charge in the industry, we know that you will be happy. Our many customers in the food processing industry have been with us for countless years because they are pleased with our proven results. No matter what kind of item needs to be coated, our customers know that we will have it back to them swiftly so that they can get back to production. When you team up with Coating Solutions, you are teaming up with a family owned company you can depend on, one who will treat you like family because we are family.